fabrication of early 20th century "sullivanesque" tin ceiling tiles finally demystified

This entry was posted on March 14 2017 by Eric

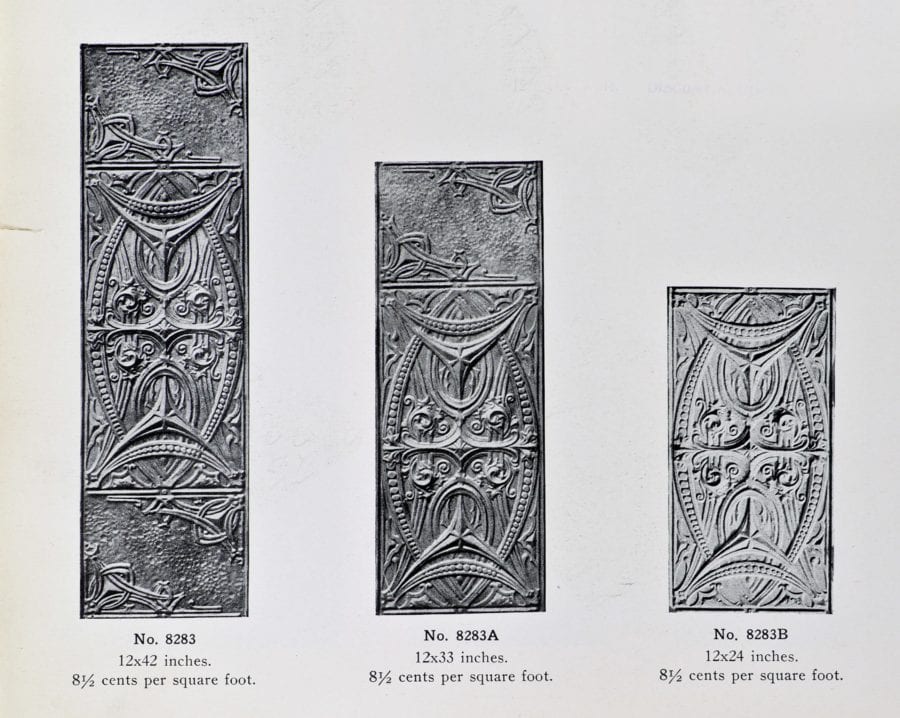

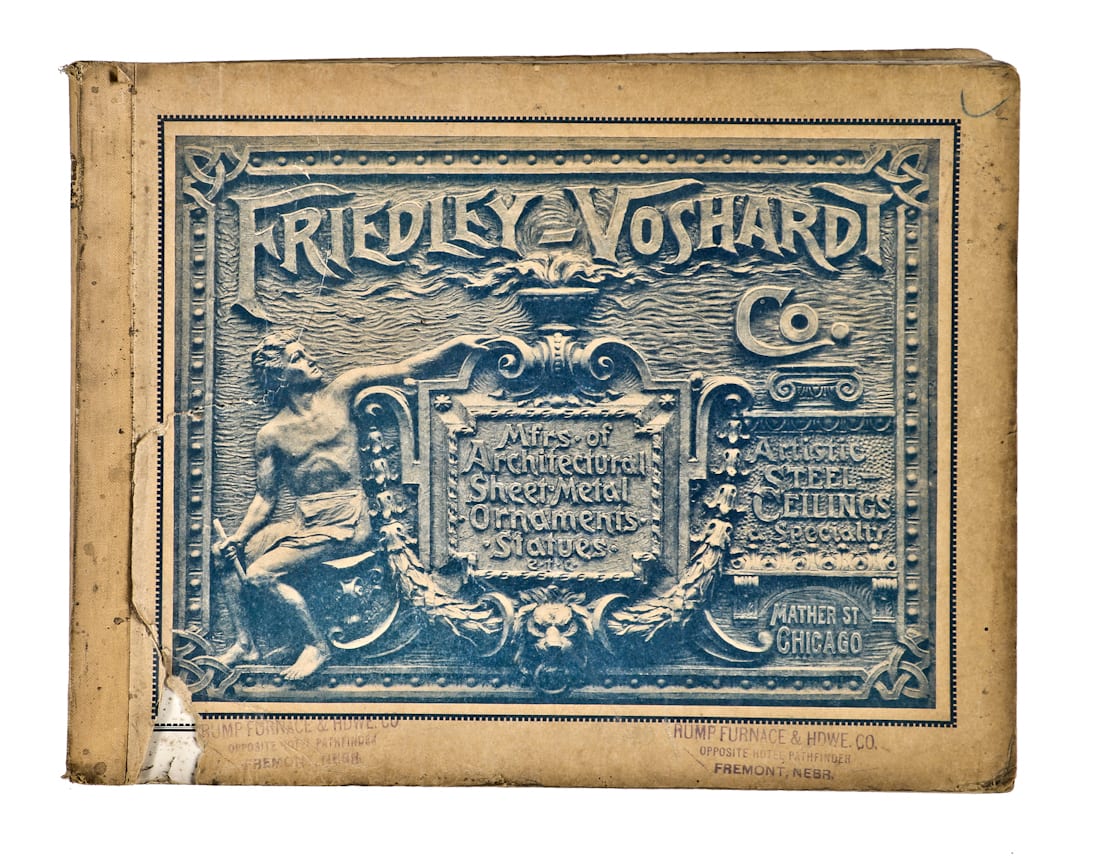

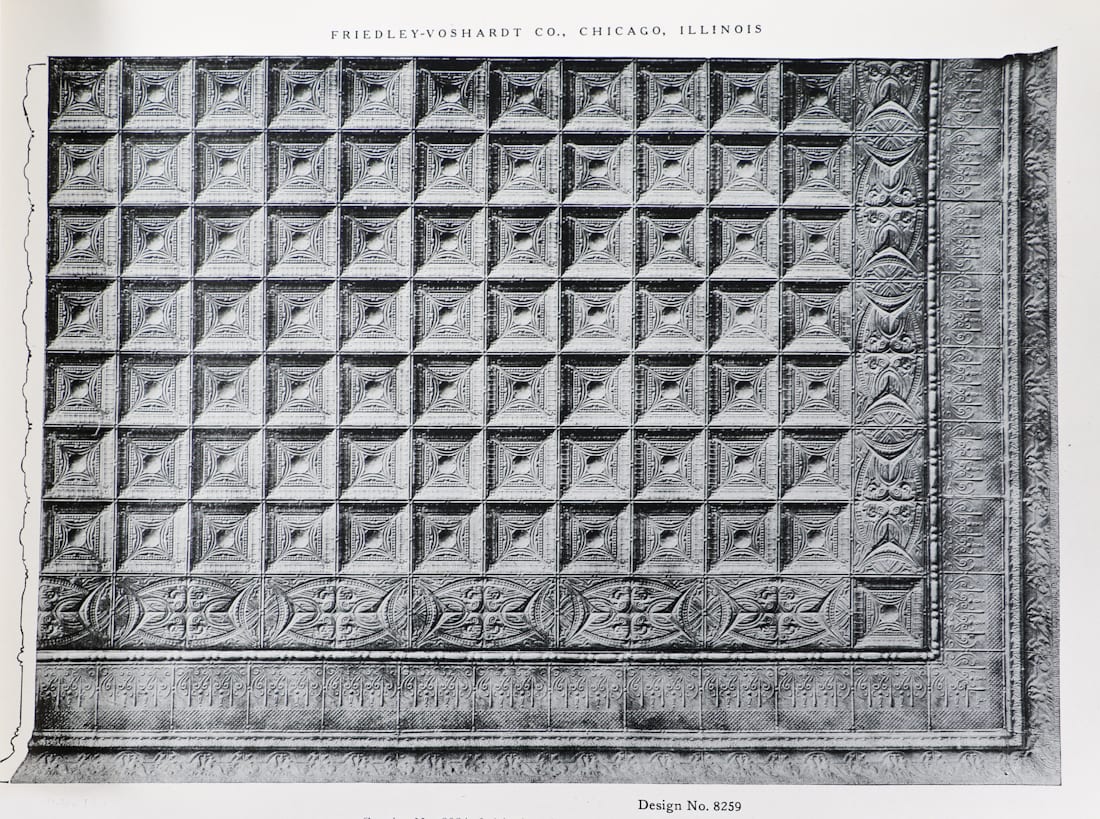

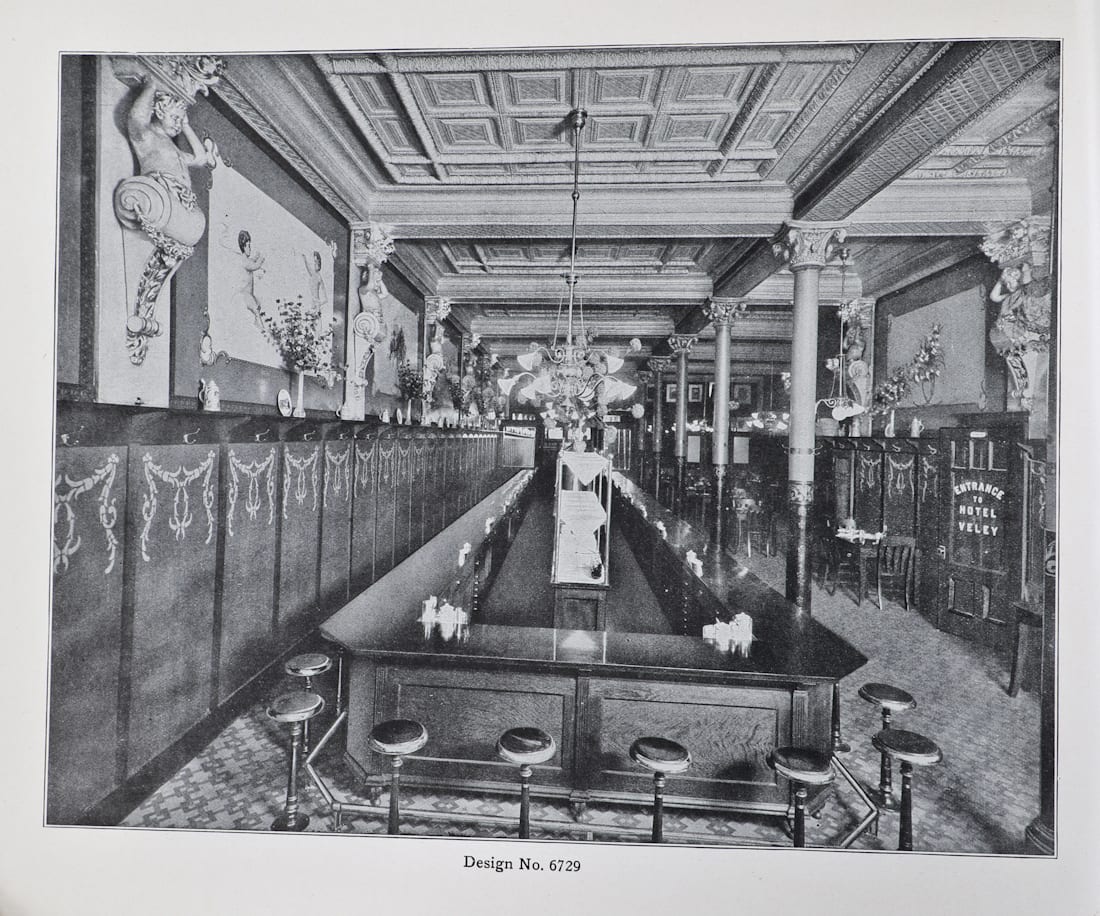

after nearly ten years, i was delighted to finally come across a catalog that definitively identifies the fabricator behind a small collection of stamped steel or tin "sullivanesque" style ceiling panels i've had in my possession all these years. this was one of the more substantial discoveries of the week, so i am pleased to share images of tin ceiling panels that now reside in the bldg. 51 collection, and the accompanying illustrations from this newly acquired catalog. the publication features several other visually striking tin ceiling patterns, along with other striking ornament (e.g., weather-vanes, gutter-spouts, cornices, signage, etc.).

company history:

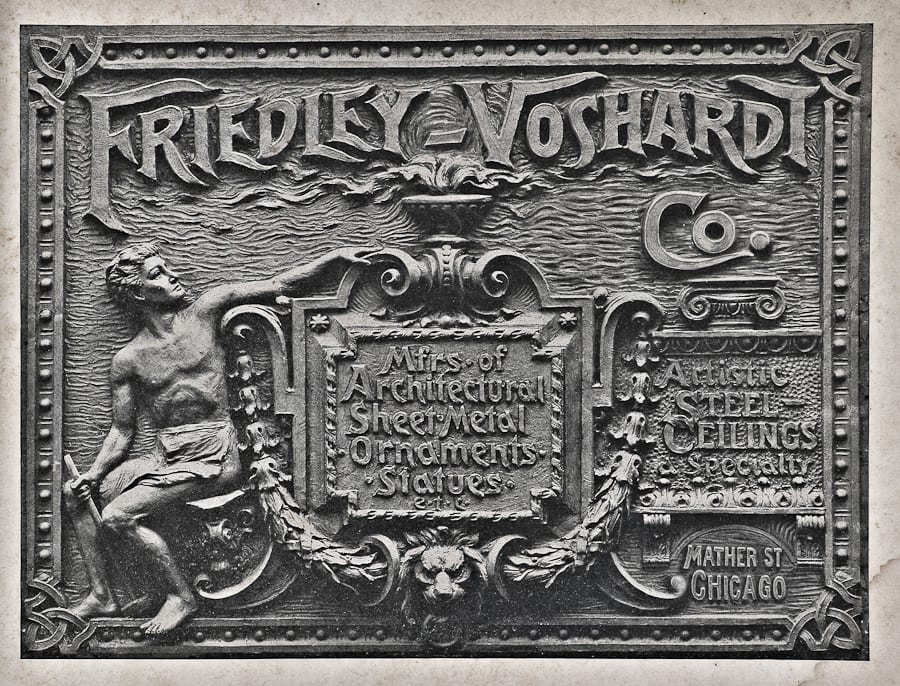

friedley-voshardt company's main offices were once at 733-737 south halsted and the factory resided at 761-771 mather street. a chicago tribune blurb from 1893 announces the company would erect a 3-story, 50 x 150 light manufacturing building at mather & halsted, after plans of d.h. laponte and at a cost of $16,000. records indicate they also seem to have occupied 1501 w. congress street during the early 20th century.

together, friedley and voshardt manufactured architectural sheet metal during the late 19th century into the late 1920's, after which time both men passed away. catalogs display an extensive assortment of figurative and decorative statues, building ornament, brass "fixture" parts or fittings, and interior tin metal ceilings. a number of patents were taken out in the names of both men, for design-work and devices associated with metalworking.

the company was purportedly founded in 1875 as "friedley & voshardt", and the first edition of its catalog didn’t appear for another 14 years. their overall manufacturing process consisted of swaging metal in sections by the use of metal dies (made from plaster casts, those in turn made from the model). the sections would be shaped and soldered and/or riveted together in such a manner as to make joints seamless or "invisible."

albert friedley and herman f. voshardt hailed from naperville, illinois, and two rivers, wisconsin, respectively. voshardt was first employed as a tinsmith in minneapolis before arriving to chicago. less information is recorded on how friedley came to be a sculptor. during their lifetime, friedley and voshardt created components for a number of historic buildings, and notably created the cornice work on the texas state capitol building during the late 19th century, as foreman for john c. mcfarland. friedley and voshardt guided the fabrication of a zinc 'goddess of liberty' statue that utilized plaster molds supplied by an unidentified sculptor (and arrived to chicago by railroad). the two reputedly set up a foundry in the southeast basement corner of the unfinished capitol, and during 1888 oversaw the casting of the 16-foot, 2000 pound statue from 80 separately welded pieces (i.e. torso, arms, and head).

the tin ceiling tiles are perhaps less monumental, but serve to connect the dots in identifying the range and craftsmanship of an important chicago manufacturer of architectural elements. with the aid of a company catalog, aged metal can spark to life, as the product of a specific factory and knowable entities.

This entry was posted in , Miscellaneous, Bldg. 51, New Products, Events & Announcements, New Acquisitions, Featured Posts & Bldg. 51 Feed on March 14 2017 by Eric

WORDLWIDE SHIPPING

If required, please contact an Urban Remains sales associate.

NEW PRODUCTS DAILY

Check back daily as we are constantly adding new products.

PREMIUM SUPPORT

We're here to help answer any question. Contact us anytime!

SALES & PROMOTIONS

Join our newsletter to get the latest information