a deeper analyis of the lumber industry as it pertains to the construction of 19th century wood-framed chicago cottages

This entry was posted on May 4 2021 by Eric

from the time of its settlement chicago had begun a lumber trade, with a sawmill on the north branch of the river that served the local construction trade, and soon after began sending timber by ox-drawn wagon to settlements along hubbard's trail. sure enough, this would become one of the most crucial fields of manufacturing during the period of industrialization in the mid-nineteenth century. lumber production heavily affected residential architecture, and with railroads eventually stretching across the plains, chicago was poised to be the hub for moving both building materials and construction methods westward. in a city of steel, stone, and terra cotta, a testament to the importance of wood is that, before the fire of 1871 fatefully set the city ablaze, most of chicago's buildings, residential or commercial, were comprised of wood and the streets were even paved with wooden blocks.

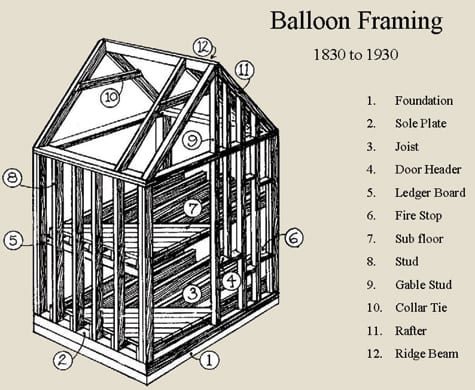

prevalent forested area in the surrounding region, as well as technological improvements over the course of the century, allowed for chicago to rely upon wood framed constructions and for balloon framing in particular to emerge as a dominant form. the advent of cheap, machine-made nails, and steam-powered sawmills likewise supported the burgeoning lumber industry and its offshoots by making specific materials and forms more economical.

in the 1830's, boatloads of lumber from as far away as michigan and canada traveled to chicago to be unloaded onto an improvised lumber yard, where customers directly sorted out planks they wanted. in the course of the 1840's chicago's strategic location allowed wood to be transported relatively easily and sold at cheaper prices than in other midwestern cities.

in the 1830's, boatloads of lumber from as far away as michigan and canada traveled to chicago to be unloaded onto an improvised lumber yard, where customers directly sorted out planks they wanted. in the course of the 1840's chicago's strategic location allowed wood to be transported relatively easily and sold at cheaper prices than in other midwestern cities.

closer afield, by the 1850's, lumber merchants were "rafting" much of their product down the waterways from wisconsin. chicago's first mayor, william ogden, was an entrepreneur on this front-- in 1856 he acquired over 200,000 acres of pineland in northern wisconsin, building sawmills, a loggers' village and a mill town at the mouth of the peshtigo river. within just a few years he was responsible for manufacturing over 50 million feet of lumber annually for chicago's market. the old growth white pines were cut during the winter harvesting season and hauled on sleds over ice skidways before being floated downriver. the laborious process entailed first transporting logs to the icy riverfront to be carried away by spring floods, beforehand marked by a "scalar" who would calculate how many board feet were in each log and stamp it accordingly, also marking the company's logo.

log drivers then performed the dangerous job of riding the logs or running alongside, steering the wood with poles or long hooks, and preventing them from jamming. the wood, in this case, was transformed into lumber--cut into boards of standard length and dimension-- closer to its destination, where it would be shipped via chicago's rails to build houses, barns, retail buildings and grain elevators across the treeless prairie. this was the typical way that most conifers of the great lakes forest reached distribution points from mill towns. in journeys in which the logs were cut into lumber beforehand, the boards were" rafted" downriver in cribs of 112 foot long logs assembled together as a 2-person operated vessel that would perilously navigate rapids and dams.

chicago's massive lumberyard accommodated this business, with entire city blocks containing only docks and yards, heaped high with wood. by 1870, more than 200 lumber boats were arriving in chicago twice a day. the lumber districts also hosted lumber-dependent industries -- furniture and piano factories, wagon and shipbuilding concerns. this in turn enabled a rise in trade of prefabricated buildings and building materials, wherein retailers like montgomery ward and sears roebuck shipped ready-made "house-kits" for cottages, schools, stores, taverns and other such structures across the country.

chicago's massive lumberyard accommodated this business, with entire city blocks containing only docks and yards, heaped high with wood. by 1870, more than 200 lumber boats were arriving in chicago twice a day. the lumber districts also hosted lumber-dependent industries -- furniture and piano factories, wagon and shipbuilding concerns. this in turn enabled a rise in trade of prefabricated buildings and building materials, wherein retailers like montgomery ward and sears roebuck shipped ready-made "house-kits" for cottages, schools, stores, taverns and other such structures across the country.

another puzzle-piece in the progression of lumber production was the availability of new saws and woodworking equipment. the process of cutting the logs down at sawmills shifted considerably with improvements to existing tools. early on, mills began to use gangs of "muley" or rip saws mounted on light vertical frames that could cut several boards at once (these replaced older, manual pit-saws and were the first type of saw to which mechanical power was applied). by the 1850's, more common were massive circular saw blades that provided greater consistency and control with increased speed. the use of the circular saw left its traces as a rounded, radial marking in the wood. by the 1880's lumber mills were using the band saw, which had the advantage of being thinner, and generating less waste than earlier machinery. though the band saw was first patented in the u.s. in 1836, it wasn't until much later in the century that it found general use.

all of these developments factored into the evolution of the balloon frame as a preferable method of construction. though its inception likely has antecedents on the east coast and even in europe, the balloon frame was truly differentiated in the midwest, and is certainly implicated in chicago's historical growth. balloon frames are well-known for having enabled widespread home building, being relatively easily constructed (and moved) by laymen. scholarship on chicago's form of light-wood framing usually differentiates it by its stick components (i.e. studs, wall plates, and lintels), which were much thinner than normal, and toenailed together by wrought iron nails or spikes. balloon frame houses were easily modifiable without collapsing, being made up of long lumber studs that were continuous between levels (i.e. the main difference between platform and balloon framing).

in the field, urban remains' salvage efforts have most often turned up nineteenth century wood framed houses that feature varied joinery, with hewn or sawn timber sill plates containing notches for studs, and typical mortise and tenon configurations at structural corners. occasionally, earlier homes even contain hand-hewn "treenail" pegs reinforcing the intersections. foundations are always either cedar post or brick rather than limestone.

the history of lumber distribution in the midwest is thus intimately tied to the invention of the railroad, prefabricated housing and millwork, improved mechanized sawmills, machine-made nails, and importantly -- an architectural form that would take chicago from being a small trading post to a thriving metropolis.

This entry was posted in , Miscellaneous, Salvages, Bldg. 51, Events & Announcements, Featured Posts & Bldg. 51 Feed on May 4 2021 by Eric

WORDLWIDE SHIPPING

If required, please contact an Urban Remains sales associate.

NEW PRODUCTS DAILY

Check back daily as we are constantly adding new products.

PREMIUM SUPPORT

We're here to help answer any question. Contact us anytime!

SALES & PROMOTIONS

Join our newsletter to get the latest information